PRODUCTS

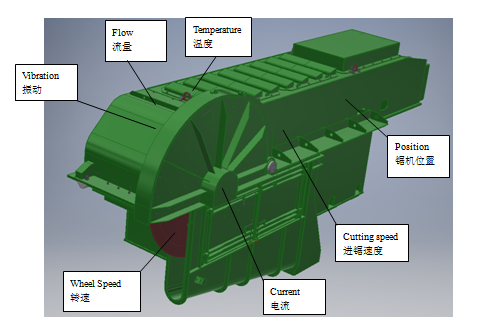

Metal Saw Data Acquisition System

I. Development Purpose

The development of a data acquisition system for metal saws aims to collect operational data from metal saws and transmit it over a network, enabling remote monitoring of the operating parameters, real-time data, and even visualized data of on-site equipment.

Based on this, after establishing LabVIEW clients and SQL databases, non-control system parameters to be collected can be determined. Combined with industrial requirements on-site, further analysis of historical data and fault analysis can be conducted, thereby improving the performance of saw machines (for example, under the premise of fully grasping the operating parameters of the saw machine in real-time, the feasibility of maximizing the use of large saw blades for cutting at rated power greatly increases). Monitoring the healthy operation of equipment and proposing maintenance suggestions for equipment maintenance. It also lays a certain technical foundation for future upgrades and transformations of saw machines through 3D design simulation twin digital technology. After the development of this data acquisition system for metal saws is completed, it can also be transplanted to the abrasive cutting saw project, and a large part of the hardware does not need to be reinvested.

In summary, the short-term goal is to be able to see the main operating parameters of the metal saw running on-site in the office in Shanghai, such as current, speed, temperature of the gear reducer, operating status, number of cutting blades, etc. And through visual monitoring, observe the operation of the equipment on-site. Another idea for this goal is to connect it to the company's website, not only serving customers and design and manufacturing, but also making a contribution to the company's external publicity and services.

The long-term goal is to gradually accumulate through further data collection and analysis, serving design improvements, maintenance services for customers, and laying the first step for KOHE's digital era.

II. Development Plan

The development plan is as follows:

1. Project Planning and Proposal Stage - Project Proposal

2. Feasibility Study Stage - Feasibility Study Report

3. Proposal ComparisonStage - Proposal Comparison

4. Implementation Stage - Hardware procurement, layout diagram, installation diagram, data acquisition processing

5. Evaluation Stage -

III. Implementation Plan

1. On-site Hardware (Various sensors, following the project)

Hardware procurement, installation. Following the project, equipment from various sensors to electrical control cabinets, including required control modules, are attached to the project. The electrical control cabinet has reserved space for installing 4G routers in advance and reserved the required 24V power supply. Additional hardware mainly involves 4G routers, installation rails, etc.

2. Office Hardware

3. On-site Data Acquisition (Reserved installation space in the electrical cabinet, installation of 4G routers. Data transmitted through 4G network via 4G router)

4. Data analysis, software programming

5. Remote maintenance, visualization display, website link

Copyright © 2017-2024 KOHE. All Rights Reserved. 沪ICP备17011245号-1

沪公网安备 31010602005675号 Designed by:Bangnie

沪公网安备 31010602005675号 Designed by:Bangnie